Experimental vs. TC Aircraft

One of the first things pilots learn is that aviation, like so many other aspects of life, is full of trade-offs. A trade-off usually refers to losing one quality or aspect of something in return for gaining another quality or aspect. It implies a decision to be made with full comprehension of both the benefits and costs of a particular choice. For example, your trusty Cessna Skyhawk may have four seats, but you probably have to leave one of them empty if you choose to top off the fuel tanks. You may relish the freedom of personal transportation that your airplane offers, but the trade-off is accepting the reality that light aircraft cannot be safely flown in all kinds of weather. Those pilots who try to have it all-be it a fully loaded and fully fueled airplane, an airline-style schedule in a small airplane, or some other combination-too often trip on the trade-offs and find themselves immortalized in the annals of aircraft accident history.

Unfortunately, recent aircraft accident history bespeaks some pilots’ failure to understand another aviation trade-off: The difference between aircraft categorized as “experimental” and those manufactured according to the standards of Title 14 Code of Federal Regulations (14CFR) part 23 (or the predecessor regulations). Statistics on amateur-built accidents show that the fatal accident rate is increasing and amateur-built aircraft fatal accidents account for an astounding 24 percent of all general aviation (GA) fatal accidents in fiscal year 2008. The numbers show three distinct spikes in accidents grouped around total hours accumulated on the airframe: The first five hours of flight for just-completed amateur-built aircraft, another spike just after the 40-hour test-flight period, and a third spike at 100 hours.

The data also indicate that “fast glass” – high-performance composite amateur-built aircraft – continue to drive amateur-built accident numbers. Since 2002, for instance, there have been 25 accidents involving amateur-built aircraft constructed from kits for the Lancair IV and IV-P. Many occurred at some point in the airport traffic pattern, and 14 of the 25 accidents involving aircraft built from these kits were fatal. These numbers suggest that some amateur aircraft builders may not entirely understand the trade-offs they are inherently making when they opt for an experimental amateur-built aircraft over an aircraft type certificated in accordance with 14 CFR part 23.

Experimental. In regulatory parlance, “experimental aircraft” is a specific term for an aircraft flown with an airworthiness certificate in the experimental category. The FAA issues experimental certificates for several purposes. These include air racing, exhibition, market surveys (e.g., sales demonstration), research and development, testing for compliance, and operating amateur-built aircraft.

Aircraft in the experimental category must be physically marked as experimental with the marks displayed near the entrance to the cabin, flight deck, or pilot station. For amateur-built aircraft, FAA Order 8130.2F, Airworthiness Certification of Aircraft and Related Products, also specifies that the operating limitations for the aircraft contain a requirement for a passenger warning placard to be displayed in full view of all occupants. This placard must state that “this aircraft is amateur-built and does not comply with the federal safety regulations for standard aircraft.”

At least 30,000 amateur-built aircraft exist in just the United States. Although many are based on conventional designs, others are very non-conventional – sometimes in terms of appearance and often in terms of performance and operating characteristics.

Part 23. The airworthiness standards for airplanes in the normal, utility, acrobatic, and commuter categories are described in 14 CFR part 23. By contrast with experimental category aircraft, those produced in accordance with 14 CFR part 23 must meet a number of requirements intended to ensure airworthiness in areas such as performance, stability, controllability, and safety mechanisms. The nature of the type design and production approval processes for aircraft produced in accordance with 14 CFR part 23 ensures that the flight characteristics of each aircraft sold under a particular make and model are precisely predictable.

Part 23. The airworthiness standards for airplanes in the normal, utility, acrobatic, and commuter categories are described in 14 CFR part 23. By contrast with experimental category aircraft, those produced in accordance with 14 CFR part 23 must meet a number of requirements intended to ensure airworthiness in areas such as performance, stability, controllability, and safety mechanisms. The nature of the type design and production approval processes for aircraft produced in accordance with 14 CFR part 23 ensures that the flight characteristics of each aircraft sold under a particular make and model are precisely predictable.

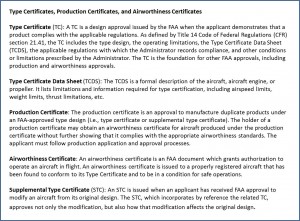

Specifically, a type certificate (TC) means that the design of the aircraft has been fully evaluated and tested. The TC includes the type design, operating limitations, the Type Certificate Data Sheet (TCDS), applicable regulations, and other conditions or limitations prescribed by the Administrator. The TC is the foundation for other FAA approvals, including production and airworthiness approvals.

During the type certification process, the design is developed and tested by the company to show compliance with the various requirements of part 23. These tests, including flight tests, usually begin with a proof-of-concept, or prototype, airplane. Once the testing has shown compliance with the regulations and meets the desired performance parameters, then the manufacturer will build “conforming” airplanes for final testing. When the company is satisfied with these test results, the FAA reviews the data and will conduct its flight tests. These tests usually occur over time and in the end the FAA makes the “finding of compliance” to the regulations. After all the data are approved and FAA completes the various flight tests, including those associated with flight performance and handling

characteristics, the FAA issues a Type Certificate.

The next step requires the manufacturer to develop processes to ensure that production will precisely and consistently replicate the approved prototype. When production and assembly processes have been approved, the manufacturer obtains a production certificate authorizing full production of the aircraft.

There is continued FAA surveillance of the manufacturer’s processes as long as the aircraft remains in production. If problems emerge in an aircraft after it enters production and service, the FAA issues airworthiness directives (AD) requiring specific action to correct the identified problems.

Note: Special-light sport aircraft (S-LSA) are not designed or manufactured in accordance with 14 CFR part 23. Rather, they are designed and produced in accordance with consensus standards developed by American Society for Testing and Materials (ASTM) and found acceptable to the FAA. These consensus standards permit the serial production of duplicate aircraft without a type certificate or a production certificate.

What’s the Trade-off? The basic trade-off between a certificated (14 CFR part 23) airplane and an experimental, amateur-built aircraft is that the experimental, amateur-built aircraft has not met any minimum performance standards. For example, a single-engine airplane certificated under 14 CFR part 23 cannot have a maximum stall speed (Vs0) greater than 61 knots, and it cannot exceed 15 degrees of roll or yaw with normal use of the flight controls during entry and recovery from a stall. An experimental aircraft, on the other hand, can have a stall speed that is much greater, and it can significantly exceed 15 degrees of roll or yaw during stall entry and recovery.

Because of the freedom that the rules provide for experimental amateur-built aircraft, even those experimental aircraft based on conventional designs may have very unconventional performance and flight characteristics. Designs that produce higher cruising speeds may offer those benefits at the expense of the more docile low-speed flying characteristics that pilots have learned to expect when flying conventional 14 CFR part 23 aircraft. It is imperative for amateur builders to recognize that the trade-offs inherent in some of today’s designs may not be benign. For more information, go to http://www.faa.gov/aircraft/gen_av/ultralights/amateur_built/.

Safety Tips. A thorough understanding of performance and handling characteristics is important for safe operation of any aircraft, but accident statistics strongly suggest that amateur builder/pilots need to go the proverbial extra mile. In aircraft designed for higher speed cruise, pilots must become extremely familiar with the aircraft’s handling characteristics at lower speeds and consider installation or retrofit of devices that enhance stall awareness. Expert flight instruction on a regular basis is also a good idea. (FAA Aviation News – NovDec 2008)